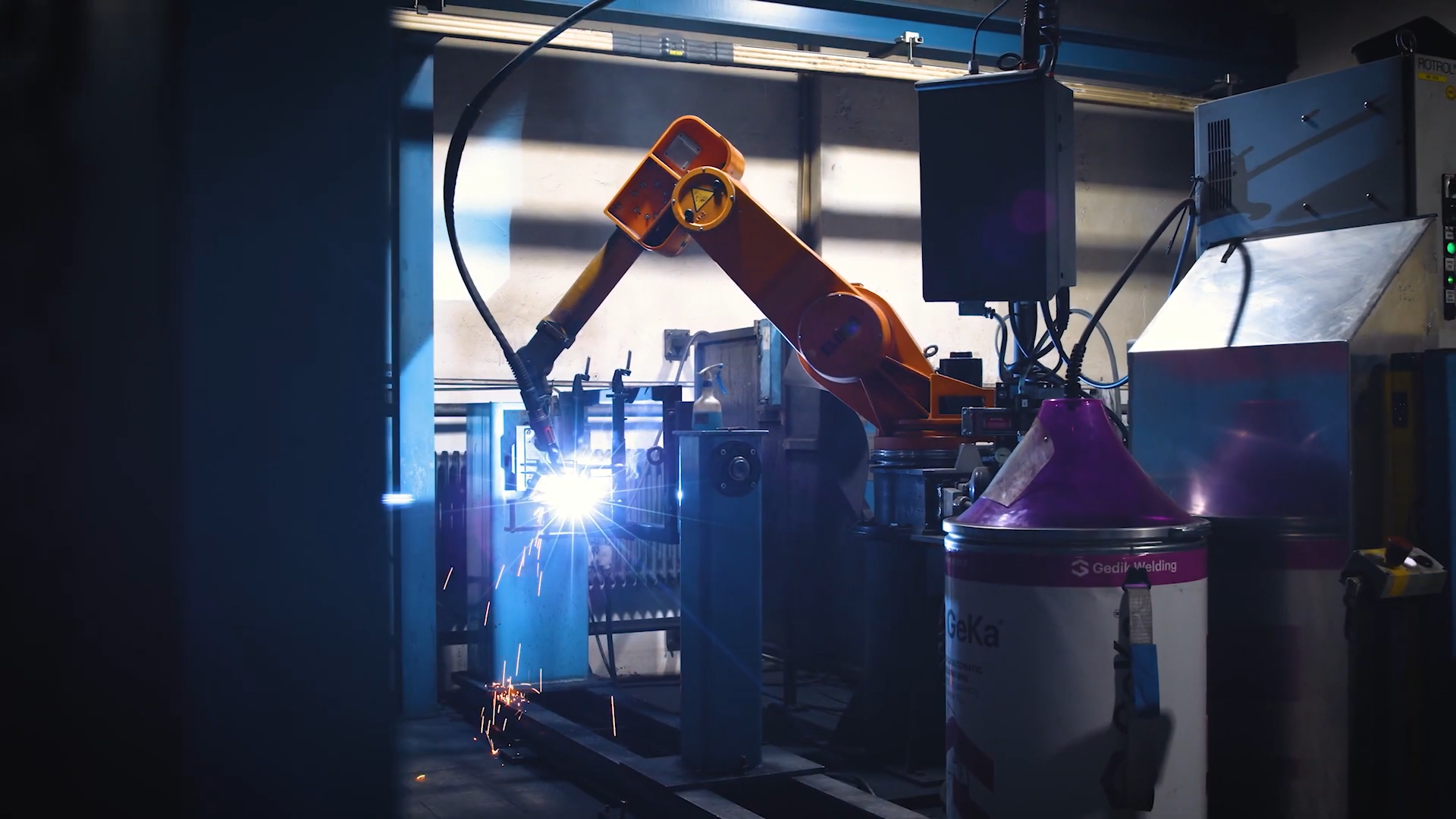

焊缝检测:检测方法和自动化

在焊接技术中,焊缝检测是品质保证的关键要素。现有多种不同的检测方法可用于识别焊接缺陷,例如焊接接头中有裂缝或未焊透。ZEISS INSPECT软件中的全新Weld Check程序包可对焊缝进行自动化和标准化无损检测。通过结合手持式ZEISS T-SCAN hawk 2,可对选定的扫描数据进行评估,非常便利。什么是焊缝检测?

焊缝检测用于检查组件的焊接质量。为了确保焊缝坚固且能够承受日常使用中产生的应力,质量控制是极为重要的。焊缝检测可直接识别和评估焊接接头处的缺陷或不连续性,例如裂纹、孔隙、气孔、异物、未焊透或形状和尺寸偏差。如何检测焊缝?

现有各种不同的焊缝检测方法,可大致分为无损检测和有损检测。如要对焊缝表面进行无损检测(NDT),可使用以下方法:目视检查、染色渗透试验、涡电流检测或磁粉检测。可通过X射线或超声波无损检测方法识别焊接接头内部的缺陷。

当使用有损焊接检测方法时,为评估焊接质量和检测焊接缺陷,需要损坏甚至毁坏焊接件。焊接的接头需要接受各种测试,例如拉伸测试、硬度测试、弯曲测试或耐腐蚀测试。这样可确定焊接接头的硬度、耐用性或抗拉强度等性能。有损检测方法通常用于检测试验对象或初始样品,而无损焊接检测方法常用于批量生产中。

无损焊缝检测方法

目视检查法

激光三角法

干涉测量法

数字图像处理法

磁粉检测法

染色渗透试验

超声波检测

X射线检测法

有损焊缝检测方法

硬度测试

拉伸测试

弯曲测试

耐腐蚀测试

自动焊缝检测与人工目视检查

焊缝检测对于检测是否存在缺陷非常重要,因为焊缝缺陷会导致零件损坏,或在最坏的情况下,导致整个焊接结构失效。这可能会对人员和环境构成很大的安全风险。因此,在许多行业中,都务必进行焊缝检测。根据检测方法和焊接设计,将采用不同的标准来确保焊接接头和焊接工艺检测的质量。

通常根据DIN EN ISO 13018的要求进行目视检查,这是最重要的检查之一,也是第一次焊缝检查。顾名思义,目视检查是由训练有素的专业人员对焊缝表面进行仔细检查。这样,可以立即检测到形状、尺寸和表面结构的任何明显偏差。然而,在目视检查焊缝时,需要克服一些挑战。根据ISO标准,应在焊接接头处充分照明,亮度至少达到500勒克斯。然而,进行检查的室内往往无法做到充分照明,且焊缝通常位于难以触及的焊件区域。这意味着通常会用到手电筒。此外,还会用到各种手动测量工具,如卡尺、三刻度尺、焊缝测量尺等。检查员利用这些工具进行多次测量,然后将结果与焊接工艺检测标准规定的容许标准进行比较。但许多手动步骤意味着很可能出错。目视检测需要花费大量时间,特别是对于难以接近的焊缝,而无法提供目视焊缝检查的数字化测试报告也使得难以追踪和检查以后出现的缺陷。自动焊缝检测可能是解决这一问题的理想解决方案。但这些焊缝检测程序能否实现自动化和标准化?

借助ZEISS最大限度地保证焊缝质量

Stahlotec GmbH向我们的HandsOnMetrology(我们的三维扫描网络)团队提出了这一问题。我们共同开发了全新“Weld Check”软件功能包。这样可根据DIN EN ISO 5817,利用三维扫描和ZEISS INSPECT检测软件实现自动焊缝检测。该标准适用于钢、镍、钛及其合金焊接接头的质量评估。手持式ZEISS T-SCAN hawk 2可用于扫描整个零件以及更小的区域,包括焊缝。通过这种方法,数秒内即可构建零件的数字化三维模型,并用于在ZEISS INSPECT检测软件中进行评估。检测软件使用全新“Weld Check”功能检测与目标值的任何偏差,并根据设定的公差进行评估。此外,即使焊缝位于难以接近的区域,也可进行可靠地检测。

通过将三维扫描系统与ZEISS INSPECT软件中的“Weld Check”功能相结合,可以对任何尺寸或形状的零件进行自动化和目视焊缝检测。该功能使用方便快捷。手持式T-SCAN hawk 2可用于测量待测焊缝所在的零件。然后将扫描数据上传到ZEISS INSPECT软件。下一步是检查焊缝。在软件中,将用一条简单的曲线来选择要检查的焊缝。然后,检查员可定义任意数量的检测区域,例如所有区域相距10mm。接下来,可以使用全新“Weld Check”功能对这些区域进行评估。此功能可自动存储DIN标准5817规定的所有特征,不仅可通过点击鼠标进行检查,还可根据相应的评估类别B、C或D直接对其进行分类。绿色表示符合标准,橙色表示焊缝刚好在允许的公差范围内,红色表示不符合标准。

在检查单个特征时,ZEISS INSPECT可用于创建单独报告或目视焊缝检查所有特征的整体日志。因此,可以通过针对每处焊缝创建检测报告,以数字化形式记录执行的所有目视检查。如果软件中存储了参考模板,例如CAD模型或三维扫描图像,还可对焊缝的位置和完整性进行检查。然后,样本扫描图像可保存为模板,并用作批量检查的基准。